Product Location AI – Finally making realograms REAL

Finally, “Product Location AI” (PLAI) is here to provide retailers with useful store maps that include automatic product location updates. Leveraging AI, barcode scans and hardware-free indoor positioning, Oriient’s PLAI seamlessly creates and maintains products’ locations, introducing the (only) sensible way to use realograms.

Plano Guides, Planograms, and Realograms are three key methods for inventory management and product location optimization. There are countless software applications and systems available to make the process “easier”. But the truth is, creating and maintaining these visual tools accurately is a costly and labor-intensive process for retailers – and anything but easy.

That’s why many retailers still don’t use them. But with the advent of COVID-19 has come the realization that not only do shoppers need to find products faster than before, but grocery pickers are working twice as hard to fill many more orders than previously. Using technology that not only creates but updates a visual map of the shop floor with accurate product placement guides makes shopping more efficient for customers and pickers.

While Plano Guides provide higher level guidelines for the space allocation of categories, and Planograms specify which product goes where, only Realograms are helpful for locating a product in real-life, as they reflect the actual placement of a product on a shelf. Realograms must be kept up to date to give an accurate picture, otherwise, they’ll have the opposite effect.

How can a realogram provide accurate real time information?

Collecting actual product locations for updating a realogram can be pricey and time consuming.

Currently, product alignment can be managed in one of three ways:

a) employee walkthroughs (in the event that you have surplus staff)

b) robots who travel the aisles and verify product location and layout (assuming you have the budget)

c) photos taken manually or by multiple cameras placed throughout each aisle that capture what’s on the shelf (a significant investment with constant maintenance costs).

For any retailer that has multiple stores, generating product-location maps for the first time is a huge investment, not to mention maintaining them.

Yet the benefits are enormous.

How can this retail pain point be alleviated, while banking some serious ROI?

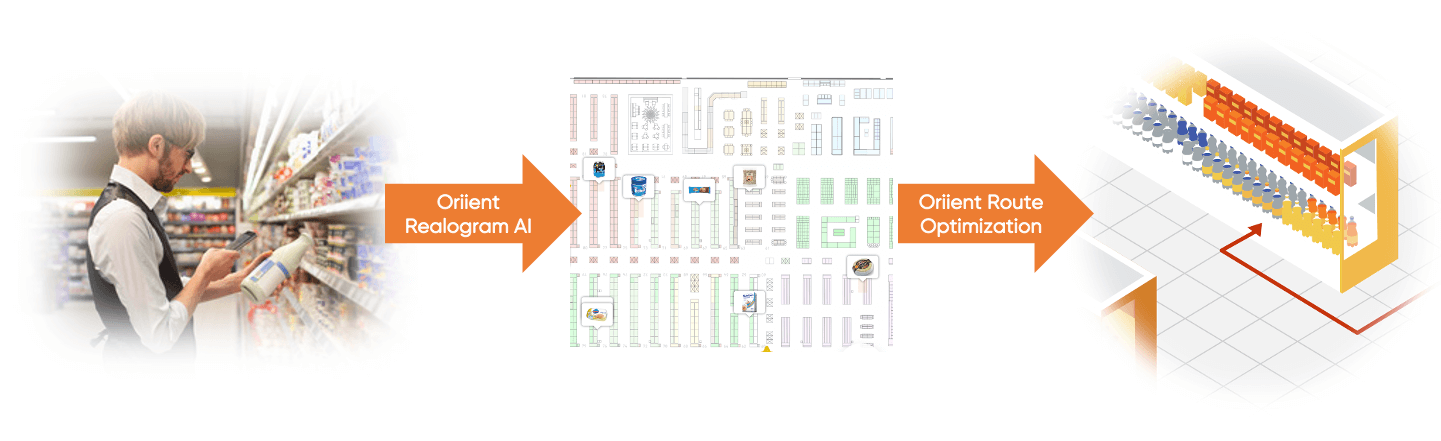

Enter PLAI: Product Location AI – the new method for creating and automatically updating product-location data. Thanks to the recent rise of product scanning apps, plus advances in indoor positioning technology, accurate locations of products (at shelf level!) can be collected passively while shoppers are using Scan & Go apps, and pickers and merchandisers are doing their typical daily work – without any extra hassle or effort.

How does PLAI work?

- Oriient’s software-only indoor GPS works transparently as an SDK in the background of the scanning app (e.g. the retailer’s Scan & Go app, the pickers’ platform, or a store handheld device), keeping track of the device’s precise in-store location.

- Each barcode scan is captured with an accurate location-tag from Oriient (within 1 meter/3 feet).

- PLAI uses an AI engine to automatically learn product locations based on where they were scanned, so that every time someone scans an item, the system receives an update with an accurate location of that scan and product. This makes the creation of a visual map and on-going maintenance effortless – thus scalable.

Oriient’s geomagnetic indoor positioning requires no costly hardware installation and is easily integrated into retailers’ existing apps. The setup is easy, uncomplicated, and takes only a matter of hours to achieve shelf-level location awareness from a simple smartphone.

Benefits and ROI

Now that we know where products are, it’s time to get more out of each shopper’s visit, and spend less time on each picking task.

Oriient offers product location maps with a route optimization engine, enabling efficient in-store navigation to easily collect all the items on a list.

– Cut Costs

By providing simple indoor product navigation to grocery picking staff, retailers can:

- Reduce picker training time by 90%, which is vital as order fulfillment demand skyrockets, making the onboarding process of new pickers virtually unnecessary.

- Improve productivity by accelerating the picking rate by 50% – allowing for more orders per picker per hour.

- Increase basket size with no more “unfound items” caused only due to the complexity of locating the product or fatigue of returning to the other side of the store.

(learn more about this here)

– Improve Shopper Experience

For the shoppers, providing in-app navigation on their smartphones enhances the brick-and-mortar shopping experience, increasing app adoption and brand loyalty, and recovering lost revenue from unfound products.

(learn more about this here)

“Executing an efficient realogram streamlines the buyer’s journey, especially when combined with an app-based store map that shows precisely where in the store their favorite items can be found.”

Forbes, November 2020

– Optimize Layout and Confirm Compliance

Oriient also supplies retailers with valuable analytical data on foot traffic and shopper behavior which provides the information needed by Space Planning and Category Performance teams to optimize the store’s layout and operations.

For the first time, this process can be based on live data, giving rise to layout A/B testing with fast feedback loops.

Then, as the optimized placement has been found, the constantly up-to-date realogram is used to confirm planogram compliance.

Finally, retailers don’t need to endlessly invest in updating the product locations on their store maps.

Are you also looking to cut costs, enhance the shopping experience, and resolve grocery picking bottlenecks?

Time to Oriient your stores!